-

Let SCGC group to provide products and services to achieve fine glass. In the glassware industry, the oxygen and hydrogen supplied by the booster gas can be used to supplement or replace gas fuel applications, thereby improving the efficiency of glass cutting or polishing. Industrial gases such as oxygen and hydrogen can also help improve heat transfer and accelerate melting or softening.

-

-

In the melting and refining process of glass, the industrial gas of the forced gas group produces bubbles, which not only helps to enhance the convection of the glass liquid, but also helps to reabsorb the residual bubbles into the glass liquid to reduce glass defects. Specific bubbling gases help improve the quality of molten glass.

-

-

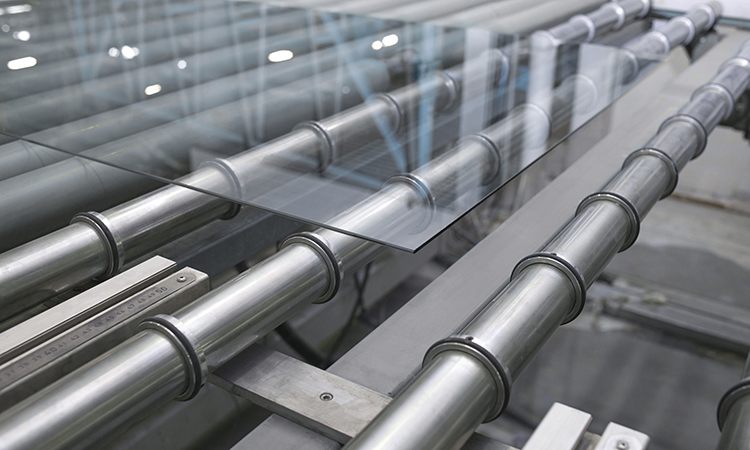

The industrial nitrogen provided by the SCGC group as a very stable inert gas can well protect the liquid tin in the tin bath of float glass production line. At the same time, the SCGC group will also match a certain proportion of hydrogen to create an inert atmosphere in the tin bath and add a reducing atmosphere to reduce part of oxygen to better ensure the working conditions of the tin bath.

-

-

SCGC Group has extensive experience in supplying industrial gases and complete solutions to the glass and fiberglass production industry. Highly customized service, excellent quality and stability have always been our commitment to customers and our key advantages in winning customers. If you would like to know more, please contact us.

-